This article outlines the overall requirements and operating modes for the establishment of quality, environmental and occupational health and safety management systems, shows the main structure and contents of the management system, and focuses on the management system planning, production and service operation planning and control, and performance evaluation And improvement, provide a reference for the organization to establish a perfect and appropriate management system.

1. Quality, environment and occupational health and safety management system requirements and operating modes

The ISO organization released ISO 9001:2015 (quality management system-requirements) and ISO 14001:2015 (environmental management system-requirements and guidelines) in September 2015, and ISO 45001:2018 (occupation) was released in March 2018 Health and safety management system-requirements and guidelines). The three standards ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 stipulate the management system requirements that organizations can use to improve their quality, environment and occupational health and safety performance, and are applicable to any type, scale and provide different products And service organization.

The quality, environment and occupational health and safety management system should be established according to relevant technical standards and the organization's own characteristics, and it needs to be distinguished from other systems. Establish a scope and process that can be determined by the organization's own management system, establish policies, assign functions, manage goals and achieve planning, risk identification and evaluation, planning and control, performance evaluation, etc., and build in a process manner.

ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 emphasize the leadership role as the core, adopt the PDCA cycle of planning, support and operation, performance evaluation, and improvement. Through planning, the main process and sub-processes are identified to determine each Interaction between processes, rationally arrange the sequence of each process, and carry out system management. The PDCA cycle can be applied to all processes and the entire management system.

2. The main structure and content of the management system

The main structure of the quality, environment and occupational health and safety management system and its contents include but are not limited to the following aspects: normative reference documents, purpose and scope of application; communication of management policies and objectives, management policies; organization and its environment, related The needs and expectations of the party; leadership roles and commitments, organizational positions, responsibilities and authorities; scope, requirements, processes and planning of the management system, including the identification and assessment of risks and opportunities; resource management, including personnel, infrastructure, and processes Operating environment, monitoring and measuring equipment, organizational knowledge, etc.; internal and external information exchange, documented information management and control; production and service operation planning and control; external provision of product and service requirements determination and control; management system performance evaluation , Correction, prevention and continuous improvement.

3. Planning of the management system

1. General

The planning of the management system should meet the requirements of relevant standards, and consider the compatibility of quality, environment and occupational health. In order to implement the quality, environment, and occupational health and safety management policies, the organization should determine the management goals within the framework of the management policies, and ensure that the goals are established in all relevant functional departments and levels, consistent with the management policies, and the resources required to achieve the goals Carry out identification and planning to realize the promise of the management policy.

Within the scope of the management system defined by the organization, the life cycle perspective should be considered when determining the environmental factors that can control and exert influence in their activities, products and services and their related environmental impacts. The so-called life cycle refers to a series of successive stages in the product (or service) system. Raw materials are obtained from the natural world or natural resources until final disposal; life cycle stages include raw material acquisition, design, production, transportation and delivery, use, and life Post-processing and final disposal. For identification and evaluation of environmental factors, the focus of information collection should consider emissions to the atmosphere and water, land pollution, solid waste management, energy conservation and consumption reduction, natural resource utilization, and noise emissions. Environmental factors should also be considered when determining: changes, including planned or new developments, and new or modified activities, products, and services; abnormal conditions and reasonably foreseeable emergencies. Environmental factors that are determined to have significant impacts on the environment or may have significant impacts should be controlled.

When an organization establishes, implements, maintains, and continuously improves its quality, environment, and occupational health and safety management system, it must consider environmental factors and occupational health and safety related compliance obligations. Compliance obligations may bring risks and opportunities to the organization. When obtaining these compliance obligations, you should consider how to apply them to your organization.

When the organization determines that the management system needs to be changed, the change should be implemented in the way it was planned, and the purpose of the change and its potential consequences, the integrity of the management system, the availability of resources, the allocation of responsibilities and authorities or Redistribution.

2. Identification and assessment of risks and opportunities

The organization shall identify and determine the risks and opportunities in the production and service activities according to the environment and related parties’ needs and expectations, in order to improve the effectiveness of the quality, environment and occupational health and safety management system and ensure that the management system can achieve its Anticipate results, enhance favorable impacts, prevent or reduce adverse impacts, and achieve continuous improvement.

The risks that should be identified include but are not limited to the following: risks caused by changes in applicable laws, regulations, standards, and customer requirements; safety and quality risks during production and service activities, and potential emergency situations; procurement risks; finance And human resource management risks; market and competition risks; related social factors, such as workload and working hours, fraud, and threats.

Evaluate the severity and frequency of risks in the identified process, plan measures for corresponding risks according to the corresponding risk level, and implement risk level control. Risk response measures include risk elimination, risk avoidance, risk reduction and risk acceptance.

3. Management objectives and planning for their realization

The quality, environmental and occupational health and safety management objectives set by the organization should be consistent with its management policy, and the results of risk and opportunity assessment and consultation with staff should be considered; the management objectives should be measurable or capable of performance evaluation, monitoring, Communicate and update timely. When planning how to achieve management goals, the organization should determine what needs to be done, what resources are needed, who is responsible, when it is completed, and how to evaluate the results, as well as how to integrate measures to achieve the management goals into the organization's business processes.

4. Operation planning and control of production and service

1. Product and service requirements, operation planning and control

To ensure that customers are provided with products and services that meet the requirements, the organization should review the customer's regulations, contract or order requirements, and laws and regulations applicable to products and services in advance. At the same time, the following measures should be used to plan, implement and control the required processes; determine the requirements of the products and services and the required resources; establish the acceptance criteria for the processes, products and services; control the planned changes and outsourcing processes; identify and evaluate the important Environmental and risk factors; identify potential emergency situations and plan emergency response measures.

2. Design and development of products and services

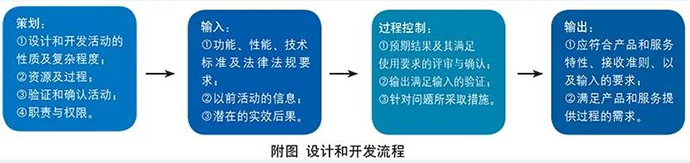

The organization shall establish, implement and maintain the design, development planning, input, process control, output and change processes to ensure the subsequent provision of products and services. In each control stage of design and development, the nature of the design and development activities, the specific types of products and services, the output to meet the input requirements, and the requirements for the process of providing products and services are mainly considered. The design and development process is shown in the attached drawings.

3. Control of production and service provision

The organization shall provide production and service under the controlled conditions of all resources (including personnel, equipment, infrastructure, operating environment, available documented information, etc.). In the whole process of production and service provision, the output status should be identified according to the monitoring and measurement requirements to achieve traceability.

When determining the coverage and degree of required products and services after delivery, the organization should consider the requirements of laws and regulations, the potential adverse consequences related to products and services, the nature and service life of products and services, customer requirements and feedback. The changes in production and service provision shall be reviewed and controlled as necessary to ensure continued compliance. Only after verifying that the requirements of products and services have met the acceptance criteria and approved by the relevant authorized personnel, can the products and services be delivered to customers.

Identify and control non-compliant output to prevent unintended use or delivery. After product delivery, and when non-conforming products and services are discovered during or after service provision, appropriate measures should be taken based on the nature of the non-conformity and its impact on product and service compliance, such as correction, isolation, restriction, return or suspension Provide products and services; inform customers; obtain concession authorization. After correcting the unqualified output, it shall be verified whether it meets the requirements.

V. Performance evaluation and improvement

In order to ensure the conformity of products and services and continuously improve the management system, the organization should monitor the quality, environment and occupational health and safety performance, and plan and implement the monitoring, measurement, analysis and evaluation process. First of all, the objects to be monitored and measured should be determined, and the monitoring and measurement methods should be planned. Analyze, evaluate and use the data and information obtained from monitoring and measurement. The contents of analysis and evaluation mainly include: the effectiveness and conformity of product and service planning and implementation, customer satisfaction; the performance of the management system and the performance of external suppliers; the effectiveness of the response measures to the identified risks and opportunities; Implementation of compliance obligations; management system internal audit reports, corrective measures and improvements.

In the process of production and service, when an unqualified event occurs or a situation that does not conform to the facts occurs, the organization should respond in a timely manner. If necessary, the cause can be determined through incident investigation or review, and appropriate corrective measures can be taken. Before taking measures, the occupational health and safety risks associated with new or changed hazard sources should be evaluated. At the same time, the results of analysis and evaluation, as well as the output of management reviews should be fully considered to determine whether there is a need or opportunity to continuously improve the suitability, sufficiency and effectiveness of the management system, and to improve the quality, environment and occupational health and safety performance, Enhance customer satisfaction, corrective actions and improvements.

The establishment of a complete management system aims to standardize the process and system management methods adopted by the organization for the implementation of quality, environment, and occupational health and safety management activities. When planning the management system, it is necessary to not only comply with relevant technical standards and laws and regulations, but also combine the organization's own characteristics and actual conditions. A suitable management system can truly guide the organization to achieve its management policies and objectives. Internally, the organization’s management can be guided by rules and laws; externally, it can confirm the continuous and effective operation of the organization’s management system and provide customers with stability and satisfaction. The required products and services realize the promise to customers and gain the trust of customers.

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn