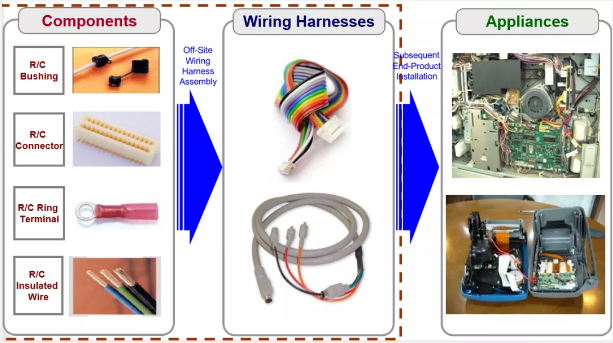

As the core competitiveness of the manufacturing industry, electronics and electrical equipment, its parts and materials usually come from a variety of fields, including widely used electronic wires and other wires. Most electronic wire (AWM) will be processed into wire harnesses before entering the final assembly stage. Therefore, the quality of electronic wires and other wire materials and traceability of raw materials have become the focus of attention.

As an important part of the manufacturing industry, electronic and electrical equipment companies and downstream wire and cable companies are also facing fierce market competition. Increasing production efficiency, improving supply chain efficiency, and expanding profit margins are particularly critical for many manufacturing companies.

To support the wire and cable business towards "poetry and distance" and reduce the risk of non-compliant cables being introduced into the supply chain, it is necessary to introduce supply chain management that meets the needs of enterprise development and achieve the improvement and optimization of the company's system.

The plan enables full monitoring of the cable from the cable manufacturer to the wire harness manufacturer to the final assembly line.

Based on the end product survey, UL built a network platform composed of more than 2,000 UL-certified wire harness manufacturers. At the same time, get in touch with suppliers, so that finished product manufacturers can confidently meet cable procurement needs, and quickly introduce new wiring harness designs into the supply chain, thereby saving time, money, and reducing pressure.

However, it should be noted that a power cord set (CordSet), or a power supply cord (Power Supply Cord) connected to a device (such as a motor), has other UL corresponding certification categories, such products are not applicable to the program.

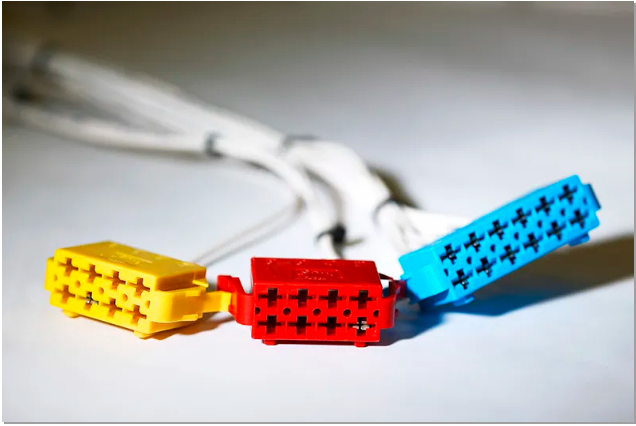

The assembly of the wire harness is carried out by the wire harness manufacturer according to the assembly drawings, engineering drawings or other specifications provided by the finished product manufacturer. The finished product manufacturer will specify the construction elements (Construction Element) and component requirements required when assembling the wire harness .

If the harness meets these specifications, the UL mark can be affixed at the time of shipment. For the traceability requirements of these constituent components, UL will further determine whether these parts meet the requirements of the product tracking and inspection service program during the factory inspection of the finished product manufacturer.

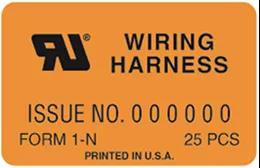

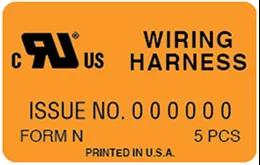

Logo label

Therefore, choosing the UL "Wiring Harness Traceability Plan" not only provides the most effective and convenient way for customers and UL inspectors, assists in identification, verifies the in-process process of parts/raw materials, but also improves the availability of wire harness manufacturers on the finished client Reliability.

UL Component Recognition (Component Recognition) requires a UL recognized part logo on the part to confirm that the part has passed the part recognition and tracking inspection services. Basically, unless otherwise stated in the published part information, the identification of an approved part should include the following:

· Certified company certificate/name

· Approved company catalog number or model

Detailed information about UL approved parts can be obtained through the UL Recognized Component Directory (Recognized Component Directory) and the official website www.ul.com/database. In addition to the content (the approved company name and model number) required by the above logo, if the approved parts are sold to the U.S. or Canadian market, they can be affixed with UL U.S. and Canada approved parts marks; if they are sold to the U.S. and Canada Ground, it can be affixed with UL's approved parts mark of the United States and Canada.

UL is committed to maintaining the traceability of the materials and components used in its certified products to ensure the continued integrity of the supply chain and encourage end product manufacturers to have more confidence in the materials they receive.

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn