COMPANY

News

HOME > COMPANY > News

Plastic materials UL certification

Date:2020/12/31 Clicks:1456

The export of plastic material products to the United States is increasing. So what is plastic material, and what certification and certification process are required to export to the United States? Today I will take you to learn about UL certification of plastic materials.

►Classification of plastic materials

Plastic material is a kind of solid material made by polymer as the basic component, after adding additives, under certain temperature and pressure, through processing and molding or cross-linking and curing. Since most polymers have good insulating properties, they are widely used as insulating materials.

1. According to thermal behavior, plastic materials are divided into two types: thermoplastic and thermosetting.

1. Thermoset plastics (Thermoset plastics): It means that after heating, the molecular structure will be combined into a network form. Once combined into a network polymer, it will not soften even if heated again, showing the so-called [irreversible Changes] are caused by changes in molecular structure (chemical changes).

2. Thermoplastics (Thermo plastics): refers to plastics that will melt after heating, can flow to the mold after cooling, and then melt after heating. Heating and cooling can be used to produce [reversible change] (liquid ←→ Solid state) is the so-called physical change.

According to the scope of application, there are mainly general plastics such as PE/PP/PVC/PS, and engineering plastics such as ABS/POM/PC/PA. In addition, there are some special plastics, such as high temperature, high humidity and corrosion resistance, and other plastics modified for special purposes.

2. Classification by use of plastics

a. General-purpose plastics: This type of plastic is a kind of very versatile plastic. It has a large output, accounting for about three-quarters of the total output of plastics. It is low in price and is used in large quantities to make daily necessities with little force, such as TV casings. , Telephone shell, plastic basin, plastic bucket. The relationship with people is very close and has become an important pillar of the plastics industry. Commonly used general plastics include PE, PVC, PS, PP, PF, UF, MF, etc.

b. Engineering plastics: Although the price of general-purpose plastics is low, its mechanical properties, temperature resistance, and corrosion resistance are difficult to meet the needs of certain engineering and equipment as structural materials. For this reason, engineering plastics came into being. High strength, high rigidity, can replace some steel or non-ferrous metal materials, can manufacture mechanical parts or engineering stress parts with complex structure, many use effects are better than the original materials, commonly used engineering plastics include PA, ABS, PSF, PTFE Plastic materials, POM plastic materials, PC, etc.

c. Special plastic materials. This kind of plastic materials have unique functions and can be used in some special fields.

►UL flame retardant test of plastic materials

UL94 is the most widely used plastic material burning level test standard, which is used to evaluate the ability of materials to extinguish after being ignited. According to the burning speed, burning time, anti-drip ability, and whether the drops are burning, there are many ways to judge. Each tested material can get many values according to the color or thickness. When the material of a certain product is selected, its UL rating should meet the requirements of the plastic part. The flame retardant grades of plastics increase gradually from HB, V-2, V-1 to V-0.

1. Grade representative:

1. HB horizontal burning (HorizontalBurn), there is only one level possible.

2. V Vertical Burn (VerticalBurn), there are 3 levels: V-0 is the highest, V-1 is the lower, and then V-2.

3.5V vertical burning (VerticalBurn), using a large 125mm flame, there are 1 or 2 levels: 5V-A or 5V-B.

4. VTM vertical thin material (VerticalThinMaterial), the possibility type is the same as that of V grade, but TM is added after V.

HB: The lowest flame retardant grade in the UL94 standard. It is required that for samples with a thickness of 3 to 13 mm, the burning rate is less than 40 mm per minute; for samples with a thickness of less than 3 mm, the burning rate is less than 70 mm per minute; or extinguished before the 100 mm mark.

V-2: After two 10-second burning tests are performed on the sample, the flame is extinguished within 60 seconds, and burning materials may fall.

V-1: After two 10-second burning tests are performed on the sample, the flame is extinguished within 60 seconds, and no burning material can fall.

V-0: After the sample is subjected to two 10-second burning tests, the flame is extinguished within 30 seconds, and no burning material can fall.

2. There are 3 main levels of testing:

1.20mm flame, the judgment result is HB, V-0, V-1 or V-2.

2.125mm flame, the judgment result is 5V-A or 5V-B.

3. The 20mm flame is for thin materials, and the result is VTM-0, VTM-1 or VTM-2.

V grade needs 5 samples, HB only needs 3 samples. When starting to test with V, but if the material shows poor characteristics in the first 2 samples, you can use the third sample left to switch the test to HB.

When the material test becomes V-0, the material can be tested with a 125mm flame test to see the possibility of 5V-A or 5V-B. However, the 5V test can only be performed when the material passes the V-0 rating.

have to be aware of is:

If the material is very thin, it cannot be tested in accordance with any V level because the material will "float" in the heat of the flame. The material should be tested as a thin material using the VTM test procedure. Similarly, the VTM test can only be performed when the material fails or cannot be properly tested in accordance with the V test procedure.

Sample size: length 125 ± 5mm

Width 13.0 ± 0.5mm

Maximum thickness is limited to 13.0mm

UL product category number: QMFZ2

►Documents required for UL certification

1. Application Form for Plastic Material Certification

2. Company business license

3. UL305: Product Submission and Testing Service Agreement

4. UL340: UL Service Agreement

5. UL337: Agency authorization notice

►Classification of plastic materials

Plastic material is a kind of solid material made by polymer as the basic component, after adding additives, under certain temperature and pressure, through processing and molding or cross-linking and curing. Since most polymers have good insulating properties, they are widely used as insulating materials.

1. According to thermal behavior, plastic materials are divided into two types: thermoplastic and thermosetting.

1. Thermoset plastics (Thermoset plastics): It means that after heating, the molecular structure will be combined into a network form. Once combined into a network polymer, it will not soften even if heated again, showing the so-called [irreversible Changes] are caused by changes in molecular structure (chemical changes).

2. Thermoplastics (Thermo plastics): refers to plastics that will melt after heating, can flow to the mold after cooling, and then melt after heating. Heating and cooling can be used to produce [reversible change] (liquid ←→ Solid state) is the so-called physical change.

According to the scope of application, there are mainly general plastics such as PE/PP/PVC/PS, and engineering plastics such as ABS/POM/PC/PA. In addition, there are some special plastics, such as high temperature, high humidity and corrosion resistance, and other plastics modified for special purposes.

2. Classification by use of plastics

a. General-purpose plastics: This type of plastic is a kind of very versatile plastic. It has a large output, accounting for about three-quarters of the total output of plastics. It is low in price and is used in large quantities to make daily necessities with little force, such as TV casings. , Telephone shell, plastic basin, plastic bucket. The relationship with people is very close and has become an important pillar of the plastics industry. Commonly used general plastics include PE, PVC, PS, PP, PF, UF, MF, etc.

b. Engineering plastics: Although the price of general-purpose plastics is low, its mechanical properties, temperature resistance, and corrosion resistance are difficult to meet the needs of certain engineering and equipment as structural materials. For this reason, engineering plastics came into being. High strength, high rigidity, can replace some steel or non-ferrous metal materials, can manufacture mechanical parts or engineering stress parts with complex structure, many use effects are better than the original materials, commonly used engineering plastics include PA, ABS, PSF, PTFE Plastic materials, POM plastic materials, PC, etc.

c. Special plastic materials. This kind of plastic materials have unique functions and can be used in some special fields.

►UL flame retardant test of plastic materials

UL94 is the most widely used plastic material burning level test standard, which is used to evaluate the ability of materials to extinguish after being ignited. According to the burning speed, burning time, anti-drip ability, and whether the drops are burning, there are many ways to judge. Each tested material can get many values according to the color or thickness. When the material of a certain product is selected, its UL rating should meet the requirements of the plastic part. The flame retardant grades of plastics increase gradually from HB, V-2, V-1 to V-0.

1. Grade representative:

1. HB horizontal burning (HorizontalBurn), there is only one level possible.

2. V Vertical Burn (VerticalBurn), there are 3 levels: V-0 is the highest, V-1 is the lower, and then V-2.

3.5V vertical burning (VerticalBurn), using a large 125mm flame, there are 1 or 2 levels: 5V-A or 5V-B.

4. VTM vertical thin material (VerticalThinMaterial), the possibility type is the same as that of V grade, but TM is added after V.

HB: The lowest flame retardant grade in the UL94 standard. It is required that for samples with a thickness of 3 to 13 mm, the burning rate is less than 40 mm per minute; for samples with a thickness of less than 3 mm, the burning rate is less than 70 mm per minute; or extinguished before the 100 mm mark.

V-2: After two 10-second burning tests are performed on the sample, the flame is extinguished within 60 seconds, and burning materials may fall.

V-1: After two 10-second burning tests are performed on the sample, the flame is extinguished within 60 seconds, and no burning material can fall.

V-0: After the sample is subjected to two 10-second burning tests, the flame is extinguished within 30 seconds, and no burning material can fall.

2. There are 3 main levels of testing:

1.20mm flame, the judgment result is HB, V-0, V-1 or V-2.

2.125mm flame, the judgment result is 5V-A or 5V-B.

3. The 20mm flame is for thin materials, and the result is VTM-0, VTM-1 or VTM-2.

V grade needs 5 samples, HB only needs 3 samples. When starting to test with V, but if the material shows poor characteristics in the first 2 samples, you can use the third sample left to switch the test to HB.

When the material test becomes V-0, the material can be tested with a 125mm flame test to see the possibility of 5V-A or 5V-B. However, the 5V test can only be performed when the material passes the V-0 rating.

have to be aware of is:

If the material is very thin, it cannot be tested in accordance with any V level because the material will "float" in the heat of the flame. The material should be tested as a thin material using the VTM test procedure. Similarly, the VTM test can only be performed when the material fails or cannot be properly tested in accordance with the V test procedure.

Sample size: length 125 ± 5mm

Width 13.0 ± 0.5mm

Maximum thickness is limited to 13.0mm

UL product category number: QMFZ2

►Documents required for UL certification

1. Application Form for Plastic Material Certification

2. Company business license

3. UL305: Product Submission and Testing Service Agreement

4. UL340: UL Service Agreement

5. UL337: Agency authorization notice

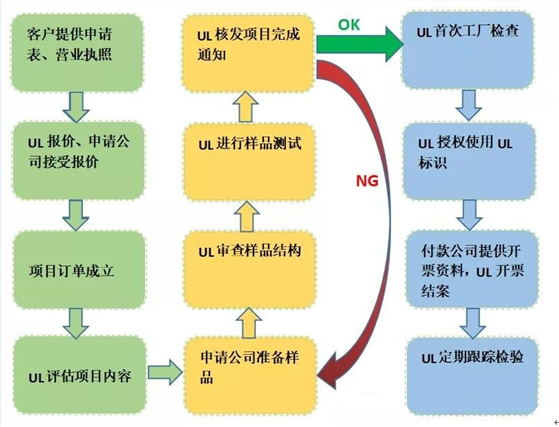

►UL plastic material certification application flow chart:

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn