With the changing needs of the market and the updating of technology, UL's standards are constantly advancing with the times. The UL certification for enameled wire is based on the 8th edition of the standard UL1446, which was released on November 13, 2019. The latest revision was on November 19, 2020. day. Also refer to the standards ASTM D2307 and NEMA MW 1000.

The structure of the enameled wire is very simple, consisting of two parts: a conductor and an insulating layer. Because of its high insulation strength, small footprint, good heat dissipation, etc., it is widely used as a coil winding in motors and transformers.

Common enameled wires can be divided into the following categories:

Whether self-adhesive

·Self-adhesive enameled wire

·Non-self-adhesive enameled wire

Conductor material

·Enameled Copper Wire (Copper)

·Enameled Aluminum Wire (AL)·Copper Clad Aluminum Enameled Wire (CCA)

Conductor shape

·Round wire

·Flat wire

Wire gauge

·Conventional enameled wire (usually enameled wire with a diameter of 0.6 mm or more)

·Fine enameled wire (usually enameled wire with a diameter of less than 0.6 mm)

use

·General purpose enameled wire

·Special enameled wire (such as corona resistance, refrigerant resistance, high voltage resistance, etc.)Paint film material

·Polyester enameled wire

·Polyurethane enameled wire

·Polyimide enameled wire, etc.

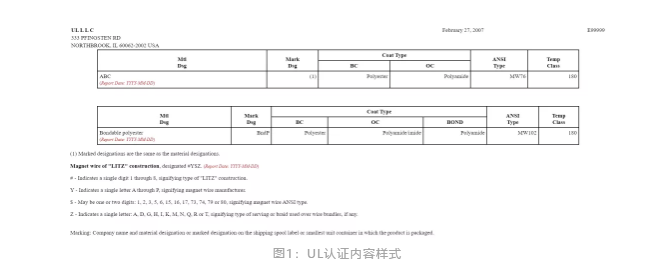

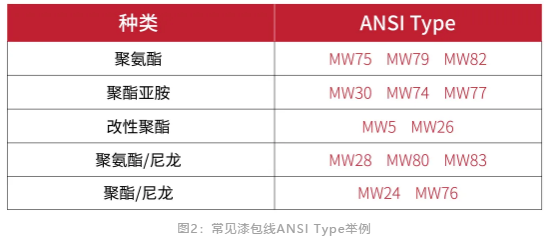

The American standard ANSI classifies the enameled wire according to the composition of the paint film, the temperature grade and the conductor type, which is our common ANSI Type, see NEMA MW1000 Page vii for details. The paint film composition, temperature grade and conductor type corresponding to each ANSI Type enameled wire are fixed. Generally speaking, round copper wires basically have corresponding ANSI Types, but flat wires and aluminum wires do not necessarily have.

Generally speaking, UL certification enameled wire requires four tests:

1. Thermal Aging Test (Full Thermal Aging Test or One Temperature Thermal Aging Test)

2. Dielectric Strength Test

3. Tensile and Heat Shock Test (Elongation and Heat Shock Test)

4. Infrared analysis test (Infrared Analysis-IR)

There are two situations for enameled wire UL certification: one is the three-temperature aging test, which refers to the situation where the paint of the enameled wire to be certified has not obtained UL certification; the other is a temperature-point aging test, which refers to the lacquer used for the enameled wire to be certified Or paint film combination has obtained UL certification. For copper clad aluminum enameled wire, even if the paint used for copper clad aluminum enameled wire has UL certification, three points of aging are also required.

For self-adhesive enameled wire, if its paint film combination, that is, all paint films including the self-adhesive layer as a whole have obtained UL certification, only one temperature point aging is required, otherwise three temperature point aging is required.

When testing, round wires can represent flat wires, enameled copper wires can represent enameled aluminum wires, and vice versa.

01 Thermal aging test

In the long-term thermal aging test, three or more temperature points are usually selected for accelerated aging, commonly known as "three-point aging".

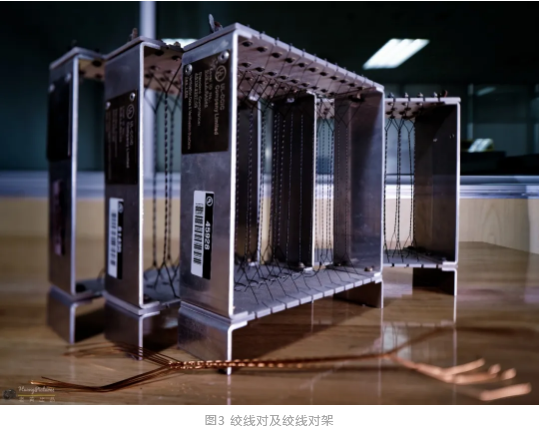

The sample for the aging test is an enameled wire twisted pair. The production of the twisted pair needs to meet the requirements of ASTM D2307 or NEMA 1000, including the weight that needs to be applied when making the twisted pair, the number of twisted turns, the effective length of the twisted wire area, and The length of the two ends of the twisted pair, etc. When making a twisted pair, the wire diameter is different, the required force and the number of twisting turns will also be different. The effective length of the stranded wire area has nothing to do with the wire diameter, the effective length is 121±6 mm, and the two ends are at least 50mm long. At least 10 twisted wire pairs at each temperature point, and installed on the twisted pair rack for high temperature aging test.

High temperature aging test process:

First put the sample into the oven for screening to ensure that all test samples meet the requirements. After the completion of the aging of the sample, after the end of each aging cycle, carry out the withstand voltage test, after the end of the test, continue with the next cycle of aging until the 10 twisted wire pairs at each temperature point are withstand voltage breakdown, and the aging test is over , Perform data analysis.How to choose three test temperature points for three-point aging?

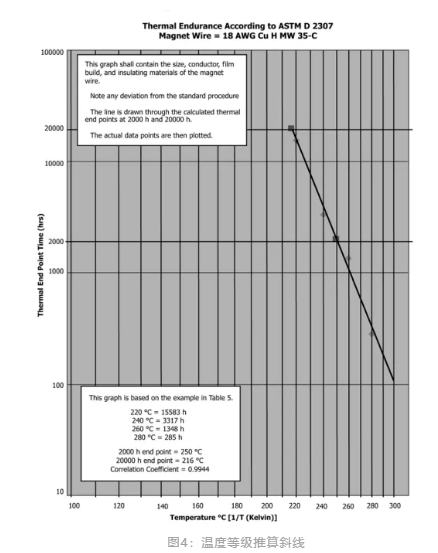

The selection of the test temperature point is based on the temperature grade applied by the customer. Usually the low temperature point will be tested at the applied temperature grade +20°C, the medium temperature point is the low temperature point +20°C, and the high temperature point is the medium temperature point +20°C. For example, if the temperature level requested by the customer is 180°C, the three aging test temperature points are usually set at 200°C, 220°C and 240°C.

The initial aging cycle of each temperature point is set according to the standard ASTM D2307 Table 3. In fact, during the aging test, it may be necessary to increase the temperature point or adjust the aging cycle according to the actual test progress.

Data requirements for three-point aging test of enameled wire:

The theoretical basis of aging test data analysis of enameled wire is the "Arrhenius equation".

After the test, the log average aging time (log average hour) at the low temperature point shall not be less than 5000 hours, and the log average hour aging at the high temperature point shall not be less than 100 hours. In addition, the correlation coefficient of the diagonal line fitted by the three temperature points shall not be less than 0.95. Otherwise, it will be regarded as a test discrepancy. In the case of meeting the above requirements, we will analyze the aging test data to calculate the temperature level that the enameled wire can achieve.

How to choose a temperature point for aging?

According to the standard UL 1446 SB4.4, the temperature point with the aging time close to 1000 hours in the test data of the UL certified enameled wire paint is usually selected for the test. Normally, the middle temperature point is taken, but if the test data of the enameled wire paint is If there is no temperature point with an aging time close to 1000 hours, the temperature point with an aging time close to 1000 hours will be selected according to the linear relationship of the original test data of the enameled wire paint. At this time, this temperature point is different from the original test temperature point of the enameled wire paint. After the aging temperature point is over, bring it into the oblique line of the original evaluation of the enameled wire paint, and the correlation coefficient shall not be less than 0.95, otherwise, it will be regarded as a test failure.

02 Insulation strength test

The sample for the insulation strength test is also a twisted pair, the number is 5 pairs. During the test, apply a voltage at a boost rate of 500V/S until breakdown, and record the breakdown voltage. The requirements for insulation strength in the NEMA MW1000 standard will vary according to different wire diameters, different paint film thicknesses, and different types of enameled wires.

03 Tensile and thermal shock test

The tensile and thermal shock test samples are three 254mm enameled wires.

First pull the enameled wire to the required elongation at a rate of 3.7-4.6 m/sec, then wind the sample after the jerky drawing on the mandrel, and then put the wound sample in the oven at the specified temperature for 30 minutes. It needs to be suspended in the oven. After leaving the oven, check whether the paint film cracked or peeled off the sample after baking. In this test, the diameter of the core rod is usually 3 times the diameter of the enameled wire.

The specified temperature of the oven is set according to the temperature specified in the NEMA MW1000 standard for the ANSI Type enameled wire, usually the enameled wire temperature class +20°C.

04 Infrared spectrum analysis test

The infrared spectrum analysis test is based on the standard UL746A, which only confirms the chemical composition of the paint film, establishes the infrared spectrum and saves it. After the enameled wire is certified, there will be a follow-up inspection service for sampling every year. The infrared spectrum of the paint film on the sample needs to be compared with the infrared spectrum established on the sample at the time of certification. The two infrared spectrums must be comparable. on.

In addition to the infrared spectrum analysis, in the annual follow-up inspection service, two tests are required for the enameled wires extracted on site: insulation strength test and tensile and thermal shock test. Thermal aging test is not required. In theory, the sample required for certification is a fully cured enameled wire. If it is an incompletely cured enameled wire, there will be two risks. One is that it may affect the performance of the aging test during certification, and the other is follow-up inspection sampling There may be differences in the atlas.

UL one-stop professional service

UL has been deeply engaged in the field of "performance materials" for decades, has deep industry experience and technology accumulation, and is recognized by the global value supply chain. The testing and certification services provided for innovative insulation material combinations are also constantly advancing with the times to provide customers with More professional and comprehensive services help customers get closer to global market demands and break through international trade barriers.

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn