Group friends ask: The key components of the whole machine for CCC certification only have CE and other foreign certifications, can it only be tested randomly?

Qunyou answered: If you have CQC, you don’t need to be random, if you don’t have it, do it.

Expert answers:

In principle, this is the case.

It is worth pointing out: Parts in the CCC catalog + sales in China = CCC certification, random testing is not allowed.

To cite two examples, a washing machine factory in Zhejiang purchased a Guangdong motor. This motor has CE and other foreign certifications and cannot be exempted from "CCC China Compulsory Certification."

South Korean washing machine companies purchase Italian motors. The export of washing machines to China requires CCC certification, but the key parts of the motor do not require CCC certification, as long as the test report of the whole machine is based on the GB/T 12350-2009 "Safety Requirements for Small Power Motors".

Questions from group friends:

1. The lithium battery wet and dry vacuum cleaner uses a battery pack. The battery pack itself has not been tested by EN 62133. Now it is sent for CE. Does the battery pack have to be tested randomly or do I need to get an EN 62133 certificate first?

2. I filed a battery pack with EN 62133 certificate on the CE certificate of the original wet and dry vacuum cleaner. Do I only need to add money to file for it or do I need to apply for the new battery pack and vacuum cleaner after relevant tests?

Group friends answered:

1. EN 62133 should be done first

2. It should only be reported

Expert answers:

1. The battery is packaged in the vacuum cleaner and tested with the whole machine. ≠ The battery pack is tested by EN 62133. These are two related but different things. The battery pack is tested according to the EN 62133 standard, which helps to pass the battery pack in the vacuum cleaner to be tested with the whole machine.

2. If the parameters are consistent with the original battery pack parameters, the "battery pack with EN 62133 certificate" only needs to be checked, and no additional difference test is required.

Group friends ask: Do you know that the adapter UL1310 standard Safety Class 2 Power Units is close to or similar to the national standard or the IEC standard?

Expert answers:

Generally speaking, UL standards form their own systems, which are quite different from IEC or Chinese national standards.

Group friends ask: Is the temperature rise requirement of the foot bath not more than 48 ℃?

Qunyou answer: The water temperature during the test in Chapter 11 should not exceed 50 ℃

Expert answers:

Qunyou responded in detail, and the water temperature in the middle volume of the foot bath should not exceed 50 ℃.

It is worth pointing out that the problem may not distinguish between temperature rise K and temperature ℃. "The temperature rise is XX ℃" is wrong, it should be "The temperature rise is XXK" or "The temperature is XX ℃".

For example, if the ambient temperature is 20.0 ℃, if the component temperature is 50.5 ℃, the temperature rise = 50.5℃-20.0℃=30.5 K.

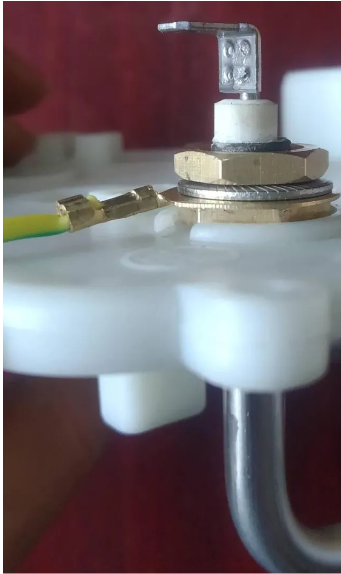

Group friends ask: I type appliances, the electric heating tube is installed and fixed on the hole of the plastic part, is there any problem with the grounding piece the picture?

Two copper nuts, grounding ring in the middle clamp and anti-loosening washer

Expert answers:

"Is there any problem this" is actually a big result derived from a series of small problems. Let's say separately:

The grounding terminal has an anti-loose gasket, which meets the requirements of anti-loose measures in clause 27.2 of the GB 4706.1-2005 standard.

The contact pressure of the ground terminal is that the two nuts clamp the ground wire ear and the anti-loose washer "hard-to-hard", and there is no non-metallic material that is easy to shrink and deform. It conforms to the GB 4706.1-2005 standard 28.2 clause. The deformed insulating material transfers the contact pressure requirements.

It seems that there is no copper-aluminum contact corrosion on the picture, and it meets the anti-corrosion requirements of clause 27.4 of the GB 4706.1-2005 standard.

In summary, from the picture, it seems that no structural problems have been found in the structure. The real object should also be tested for grounding resistance (27.5) and nut torque (28.1).

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn