If you want to make the cable test up to the standard, the test of the rubber performance of its insulating material is a barrier that cannot be bypassed. At the same time, the understanding of cable rubber performance can help us to improve the development of cable products and the improvement of production processes. Cable Bao just discussed the performance of cable rubber with industry colleagues.

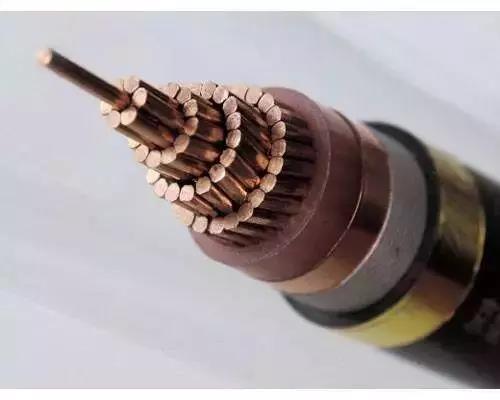

First of all, we should know that the cable insulation protection layer material is generally made of cross-linked polyethylene. The two major cross-linked polyethylene materials, ethylene-propylene rubber and silicone rubber, are commonly used materials for cable insulation and protection. Therefore, it is of great significance for cable inspection to understand the performance characteristics of these two rubbers. Let's analyze the detection of ethylene propylene rubber and silicone rubber.

1. Ethylene-propylene rubber performance for cable testing

The advantages of ethylene propylene rubber performance are that it has good weather resistance, heat aging resistance, ozone resistance, corona resistance, tracking resistance, and voltage resistance. ethylene propylene rubber has good resilience and resistance at low temperatures. Flexibility, and ethylene-propylene rubber also has good chemical stability, color stability and good colorability, so the detection of these indicators in the cable inspection is the key inspection item. In addition, ethylene-propylene rubber has poor vulcanization performance, poor oil resistance, flammability, self-adhesiveness, and poor mutual adhesion. These are all points that need attention in the detection of ethylene-propylene rubber cables.

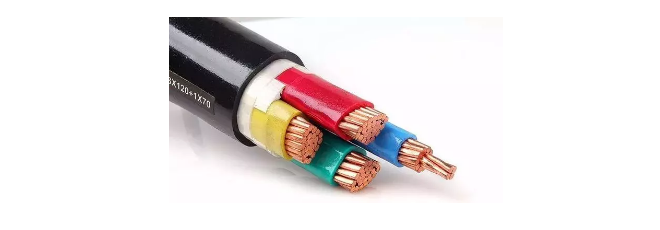

2. Silicone rubber performance for cable testing

After talking about the performance of ethylene-propylene rubber, let’s take a look at the performance of silicone rubber. Compared with ethylene-propylene rubber, silicone rubber has better performance. Because silicone rubber has high heat resistance and cold resistance, silicone rubber cables can be used in extremely wide Use within the temperature range. Excellent corona resistance, arc resistance, thermal conductivity, air permeability, etc. make the electrical insulation performance of silicone rubber extremely good. In addition, high hydrophobicity, low water absorption, ozone aging resistance, light aging, atmospheric aging, radiation resistance, oil resistance, flame retardancy, mildew resistance, etc., make silicone rubber cables have both anti-aging and service life Longer. Of course, there are so many advantages of silicone rubber cable, which makes its price more expensive. The key point of performance testing is that silicone rubber has low mechanical properties, poor acid and alkali resistance, and poor high temperature water vapor resistance.

Secondly, what are the test items specified by the cable test standard for rubber materials? There are 11 major test items for cable rubber performance, mainly including original tensile performance, tear strength, tensile performance after hot air aging, and artificial climate (xenon lamp) Tensile properties after aging, tensile properties after immersion in silicone oil, volume resistivity at 20°C, power frequency dielectric loss tangent, power frequency dielectric constant, power frequency breakdown dielectric strength, resistance to tracking and corrosion, fixed extension Items such as permanent deformation.

The cable rubber performance testing method is mainly based on the GB/T 2951 series, mainly including the following items:

GB/T 2951.11-2008 General test methods for insulating and sheathing materials of electric and optical cables-Part 11: General test methods Thickness and dimensions measurement Mechanical performance test

GB/T 2951.12-2008 General test methods for insulation and sheath materials of electric and optical cables-Part 12: General test methods Thermal aging test methods

GB/T 2951.13-2008 General test methods for insulating and sheathing materials of electric and optical cables Part 13: General test methods Density determination method Water absorption test Shrinkage test

GB/T 2951.14-2008 General test methods for insulation and sheath materials of electric and optical cables-Part 14: General test methods Low temperature test

GB/T 2951.21-2008 General test methods for insulation and sheath materials of electric and optical cables Part 21: Special test methods for elastomer mixtures Ozone resistance test Hot extension test Mineral oil immersion test

GB/T 2951.31-2008 General test methods for insulating and sheathing materials of electric and optical cables-Part 31: Special test methods for polyvinyl chloride mixtures High temperature pressure test Anti-cracking test

GB/T 2951.32-2008 General test methods for insulating and sheathing materials of electric and optical cables-Part 32: Special test methods for polyvinyl chloride mixtures Weight loss test Thermal stability test

GB/T 2951.41-2008 General test methods for insulating and sheathing materials of electrical and optical cables. Part 41: Special test methods for polyethylene and polypropylene mixtures. Environmental stress cracking resistance test. Melt index measurement method. Direct combustion method to measure carbon black in polyethylene And (or) the mineral filler content thermogravimetric analysis (TGA) measurement of carbon black content microscopic method to evaluate the carbon black dispersion in polyethylene.

GB/T 2951.42-2008 General test methods for insulating and sheathing materials of cables and optical cables. Part 42: Special test methods for polyethylene and polypropylene mixtures. Tensile strength and elongation at break test after high temperature treatment. Winding test air after high temperature treatment Winding test after thermal aging to determine the increase in quality, long-term thermal stability test, copper catalytic oxidation degradation test method

GB/T 2951.51-2008 General test methods for insulating and sheathing materials of electric and optical cables. Part 51: Special test methods for filling pastes. Dropping point oil separation. Low temperature brittleness. Total acid value. Corrosiveness. Dielectric constant at 23℃ and 100℃ DC resistivity

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn