The main problems of unqualified products are the structure, conductor size, conductor resistance, insulation and tensile strength of the sheath before aging. Consumers using such products are prone to electric leakage, electric shock or even fire hazards. These inferior products Many hidden dangers are buried in the normal operation of the power system.

1. After a single-phase grounding (short-circuit) accident occurs in the wire and cable, the relay protection device is not actuated to cut off the fault, which causes the wire and cable to overheat and cause spontaneous combustion of the insulation layer.

2. Wire and cable with qualified tensile strength and elongation of sheathed insulation before aging. The unqualified tensile strength and elongation of the insulating sheath before aging directly greatly shorten the working life of the wire and cable, and during construction or in a long-time energized environment with high temperature, the insulator is easily broken, resulting in a live conductor Exposed, there is a risk of electric shock short-circuit.

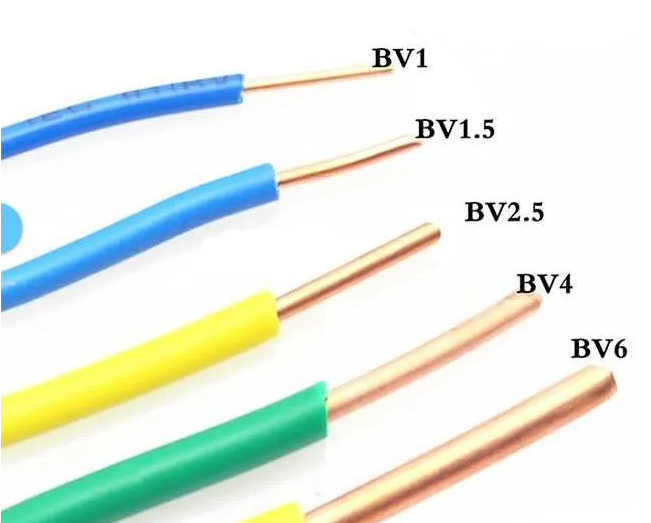

3. Wires with unqualified conductor resistance. Conductor resistance is mainly an important indicator for assessing whether the conductor materials and cross-sections of wires and cables meet. When the conductor resistance exceeds the standard, the loss when the current passes through the line is increased, and the heating of the wire and cable is aggravated. The main reason for the unqualified conductor resistance is that in order to reduce the cost, the company shrinks the copper material that accounts for 80% of the raw material cost, either reducing the cross-sectional area of the conductor, or using recycled copper with excessive impurities, which causes the conductor resistance of the wire and cable to be serious. Exceeding the standard, in addition to easy to cause fire during use, it will also accelerate the aging of the insulating layer covering the wire.

4. The insulation layer of wires and cables will gradually age during normal operation, and their service life is generally 15-20 years. If the wires are often overloaded or overvoltage due to use time, the thickness of the insulation layer is not up to the standard, and the installation is improper (such as cable If the bending radius is too small, the diameter of the wire protection tube is too small), etc., may cause accidents.

5. Wires and cables with unqualified structural dimensions. The main problem of the structure size is the thickness of the sheath and the insulation thickness. When the sheath and insulation thickness of the cable are not up to the standard, the electric resistance strength of the wire and cable will be seriously reduced, resulting in the shortening of the service life of the wire and cable, and in severe cases, the wire and cable may be damaged. Breakdown, the insulation (sheath) layer fails to provide normal protection, resulting in electrical short circuits and fires.

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn