In the 2021 spot check plan, household and similar use plugs and sockets (hereinafter referred to as "plugs and sockets") products are included. In recent years, plug and socket products (including multi-function sockets with power adapters) have been listed in the country almost every year. The supervision and spot check plan highlights the importance of the quality and safety of plug and socket products!

First, briefly introduce the content of this year's implementation rules for the national supervision and random inspection of the quality of household and similar plugs and sockets (draft for comments):

1. Sampling method

Take random samples from the products to be sold by the sampled producers and sellers.

Random numbers can generally be generated using random number tables and other methods.

24 samples are taken from each batch of products, of which 12 are used as inspection samples and 12 are used as spare samples.

2. According to the standard

GB/T 2099.1-2008 Household and similar plugs and sockets Part 1: General requirements

GB/T 2099.3-2015 Household and similar plugs and sockets Part 2-5: Particular requirements for converters

GB/T 2099.7-2015 Household and similar plugs and sockets Part 2-7: Particular requirements for extension cords and sockets

GB/T 1002-2008 Single-phase plugs and sockets for household and similar purposes. Types, basic parameters and dimensions. Currently valid corporate standards, group standards, local standards and product quality requirements

*According to the preliminary judgment based on the standard, the sampling products include plugs, wall sockets, converters and extension cord sockets

3. Inspection items

Dimensional inspection, electric shock protection, grounding measures, fixed socket structure, plug and mobile socket structure, moisture resistance, insulation resistance and electrical strength, temperature rise, force required to pull out the plug, bending test, heat resistance, climbing The electrical distance, the electrical gap and the distance through the sealant, the resistance of the insulating material to abnormal heat, flame resistance and tracking resistance.

*For products that implement corporate standards, group standards, and local standards, the inspection items shall refer to the above content.

In addition, according to the National Supervision and Random Inspection Report issued last year, the enterprises and the inspection institutions to be inspected are determined by the "double random" method, that is, the sampling inspection institutions are selected through bidding, and the random inspection enterprises are randomly selected through the "double random" information system, and random matching Inspection agency. In addition, separate sampling inspections are implemented. In addition to on-site inspections, product sampling and inspection are carried out by different institutions or different personnel within the institutions.

Next, let’s introduce the unqualified items and the proportions of plug and socket products in the sampling inspection process in the past three years:

Ordinary plug and socket products

Serial number

Unqualified items

The number of occurrences

Percentage

1

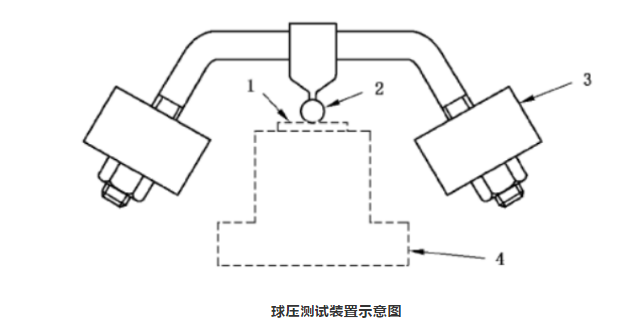

Heat resistance (ball pressure test)

11

35.5%

2

Dimensional inspection

7

22.6%

3

Protection against electric shock

5

16.1%

4

Flexible cable and its connection

4

12.9%

5

Flame resistance (glow wire test)

3

9.7%

6

Mobile plug socket structure

1

3.2%

Extension cord socket (with power adapter) multifunctional product

Serial number

Unqualified items

The number of occurrences

Percentage

1

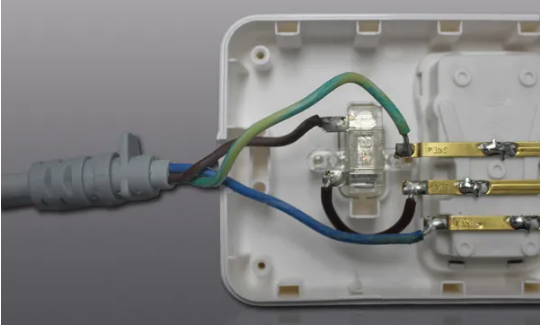

Structure of extension cord socket

5

27.8

2

Flexible cable and its connection

4

22.2%

3

Heat resistance (ball pressure test)

3

16.7%

4

Protection against electric shock

2

11.1%

5

Creepage distance, electric clearance

2

11.1%

6

Flame resistance (glow wire test)

1

5.6%

7

Dimensional inspection

1

5.6%

According to the analysis of the unqualified items and the actual unqualified situation, the reasons for the unqualified are product design problems and product consistency problems, such as the heat resistance of insulating materials (ball pressure test) and heat resistance (glow wire) If the project is unqualified, it can basically be determined that there is a problem with the consistency of the insulating material, and the insulating material used in actual production cannot meet the standard requirements.

The structure of the extension cord socket is unqualified, and the situation is relatively complicated. Common problems include Article 14.9. For non-rewirable non-molded products, the free amount of grounding wire is required to be greater than that of LN wire. The possible reason is that it is in mass production. , Failing to strictly follow the specified stripping length, resulting in unqualified actual products. It is recommended to design the stripping length so that the grounding wire has a significant margin to avoid critical situations. It is judged as unqualified during product testing. Qualified, Article 14.10.2, is also a similar situation.

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn