The bus bar is a closed metal device composed of copper and aluminum bus bars, which is used to distribute greater power to each component of the distributed system. Wire and cable have been increasingly replaced in indoor low-voltage power transmission trunk line projects.

Developed countries abroad, as well as Hong Kong and Macau in our country, have become popular. In Guangzhou, Guangdong, China, where the distribution room of buildings with more than 12 floors is used, more than 90% of the main lines leading to the floor use bus ducts; 630KVA transformers to the distribution cabinets should use bus ducts.

Scope of CCC certification of bus duct:

Suitable for low-voltage busbars with AC rated voltage of 1000V and below (frequency not exceeding 1000 Hz) or DC rated voltage of 1500V and below.

Certification category

product name

Certification standards

0301-CCC

Low-voltage switchgear

GB / T7251.6-2015

Interpretation of the conventional certification parameters of busway:

Bus trunk unit: InA = 4000A ~ 1600A, Icw = 80kA; tap unit: Inc = 320A, Icc = 50kA; Ue = 400V, Ui = 660V; 50Hz; IP65 (without tap unit) / IP54 In means: Rated working current Icw means: Rated short-time withstand current Ue means: Rated working voltage Ui means: Rated insulation voltage IP means: Protection class

Inspection items (based on standard GB / T 7251.6-2015):

a. Wiring, operating performance and functions 11.10

b. Corrosion resistance 10.2.2

c. Thermal stability verification of the housing 10.2.3.1

d. Verification of insulation materials to withstand abnormal heating and fire caused by internal electrical effects 10.2.3.2

e. Ultraviolet (UV) radiation verification 10.2.4

f. Improve 10.2.5

g. Mechanical impact test 10.2.6

h. Logo 10.2.7

i. Ability to withstand mechanical loads 10.2.101

j. Thermal cycle test 10.2.102

k. Protection level of complete equipment 10.3

l. Clearance and creepage distance 10.4

m. Protection against electric shock and protection of circuit integrity 10.5

dielectric property 10.9

0. Temperature rise verification 10.10

p. Short circuit withstand strength 10.11

q. Electromagnetic compatibility (EMC) 10.12

r. Mechanical operation 10.13

s. Verification to prevent flame spread 10.101

t. Fire protection in building structure 10.102

u. Phase conductor and fault circuit 5.101

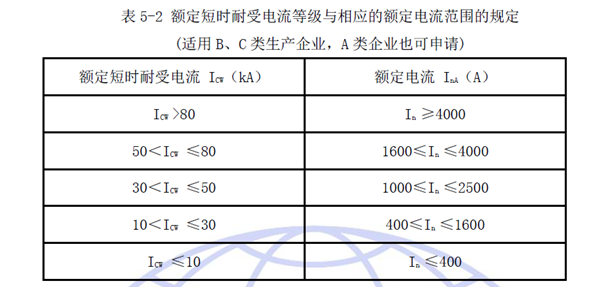

Requirements for the division of busbar CCC units:

Sample requirements for type testing:

Usually, the same rated short-time withstand current level, the product with the highest rated current is selected as the sample. The specific quantity and requirements are as follows:

1. Busbar slot: 3 sections, total length ≥6 meters; 1 section of the 3 sections is the feeder unit, 2 sections are the bus trunk line unit; 1 section of the straight line section is ≥3 meters.

2. Tap unit (if any): One tap unit is used as a sample (should include a plug-in box with the protection device of maximum rating). The plug-in tap-off unit should be installed in a straight section ≥ 3 meters, and the installation location is 1.5 meters from the center of the socket to the end.

3. Test samples to prevent flame spread (if applicable): the straight section of the bus trunk line, at least 3 meters in length, and at least 1 connection point and bus trunk line unit with tapping device (if any); 3 small currents of the same type Or send one when the width is wide (negotiation between factory and laboratory); the same series of products can be sent only one unit of samples after CQC and laboratory evaluation; when conditions permit, the flame spread prevention test can also be accompanied by samples for electrical safety tests To be done.

4. Fireproof test samples in building structure (if applicable): 1 section of busbar fireproof unit samples shall be added.

5. Requirements for refractory busbars (if applicable): The specifications and quantity of samples for refractory busbars shall be in accordance with GA / T537-2005 and laboratory requirements. 6. Sample requirements for strength test of materials and components:

①Representative samples of shells made of ferrous metal materials, internal and external ferrous metal structural components (corrosion resistance verification): various metal materials, with or without protective layers, with protective layers of different materials 5 pieces for different samples.

② Samples of insulating materials used to insulate, fix and support current-carrying parts (verification of insulation materials against abnormal heating and fire caused by internal electrical effects): busbar supports, partitions, bolt sheaths and other insulating materials Yes) 3 pieces each; heat shrinkable tube, film and other insulating materials (if any) 3 pieces each; φ100 mm (or 100mm × 100 mm) × thickness (3 ~ 5) mm: 2 pieces of each material.

③ Test samples of the shell and exterior parts of complete equipment made of insulating materials or made of metal but completely covered with synthetic materials and used for outdoor installation (verification of ultraviolet (UV) radiation resistance): the insulating materials or synthetic The number of material samples is at least 20, and the shape and size requirements are in accordance with the standards.

④Experiment sample of shell made of insulating material (verification of thermal stability of shell): 1 section of shell made of insulating material, with a total length of at least 1 meter (or 1 set). Note: The strength test of materials and components can also be carried out in combination with the materials / components in the sample machine, and verified in representative samples and samples to avoid repeated tests.

3c certification process for busway:

1. Application (intended application, formal application)

2. Type test

3. Inspection of the quality system of the production plant

4. Issuance and management of certification certificates and certification marks

5. Follow-up inspection and supervision and management after obtaining the certificate

Guangzhou Saida Testing Technology Co., Ltd. was established in 2006. It is a professional testing organization recognized by the China Conformity Assessment Commission (CNAS) (accreditation number is L6277). It is a cooperative witness laboratory recognized by well-known certification organizations such as CQC, UL, VDE, TUV It is a third-party service organization dedicated to providing professional and fast national safety certification, testing and training services for domestic and foreign enterprises. The company maintains a leading position in the field of electronic appliances, fire protection products, machinery and pressure equipment, personal protection products, building materials, chemical testing and other fields.

Enterprises are welcome to call us:

Phone: 020-39211670 ext. 0

Fax: 020-39211640

E-mail: info@certitek.cn

Website: http://www.ctktest.com

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn