COMPANY

News

HOME > COMPANY > News

Overview of CCC certification of LED lamps

Date:2020/5/25 Clicks:1325

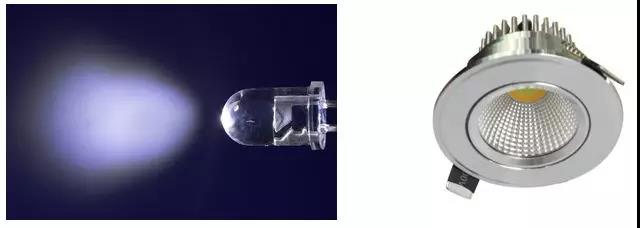

Luminaires are one of the most frequently used electrical products in our homes. Consumers are most interested in the quality of luminaires when they start to buy luminaires. In recent years, the quality of luminaires on the market has been frequent. More concerns and worries. LED lamps and lanterns are becoming the main products of the new generation lighting market due to their technical characteristics of high efficiency, energy saving, safety, longevity, compactness, and clear light, and are effectively driving the rapid development of the environmental protection and energy saving industry. In this issue, we will explain the common problems related to safety requirements in the CCC certification of LED lamps by way of question and answer.

①Installation method; ②Type of light source; ③Protection class against electric shock; ④Protection class of enclosure; ⑤Mounting surface material and heat insulation material cover; ⑥Light control device; The above 6 points are the same and the structure is similar can be divided into the same unit.

Note: For certified products of LED lamps and LED control devices, for certified products with nominal power and measured power ≤ 25W and for certified products with nominal power or measured power> 25W, they cannot be in the same unit.

(2) Q: What are the requirements for parts used in products?

a) If the parts themselves are within the scope of CCC certification, they must have CCC certification.

Such as: power cord; AC electronic control device (driver) for LED module; electronic / inductive ballast for fluorescent lamp

b) If the component itself does not have CCC certification, try to choose a CQC certified component.

Such as: screw lamp holder; fluorescent lamp holder; terminal; flexible switch

c) Some optional parts can be added appropriately.

(3) Q: What are the forms of protection against electric shock?

Class Ⅰ-basic insulation, protective grounding;

Class Ⅱ-double insulation / reinforced insulation;

Class Ⅲ-Power supply voltage SELV Lamp working voltage SELV.

(4) Question: Which parts of Class Ⅰ lamps must be grounded?

There is only basic insulation between the live parts and can touch (when the installation is completed, when the light source or starter is replaced to open) or metal parts that are easily in contact with the support surface.

(5) Question: What positioning and protective measures should be taken for power terminals?

Insulation pads are generally placed under the terminal and fixed with double screws. The purpose is to prevent a strand of free conductor that may come out of the stranded conductor after wiring from contacting metal parts (for power conductors) or live parts (for grounding conductors) .

(6) Q: What are the restrictions on the use of self-tapping screws?

Unless there is a suitable locking device (such as a spring washer), self-tapping screws cannot be used to connect current-carrying parts; unless there are at least two at each connection, self-tapping screws cannot be used to provide ground continuity.

(7) Question: How to judge which parts of the glass or translucent cover need to be impact tested according to the requirements of fragile parts?

After the removal of these components, determine whether the IP protection level of the lamp is reduced, whether the protection against electric shock is still up to standard, and whether the protection against ultraviolet rays and light source sputtering hazards is still up to standard. If there is any negative judgment, it should be regarded as a fragile part and subjected to an impact test.

(8) Q: What are the mechanical performance requirements for live flexible cables used to hang lamps?

The flexible cable with a sufficiently large conductor cross-sectional area should be selected so that the stress of the conductor during suspension is not greater than 15N / mm2, and the weight of the weight suspended by the flexible cable cannot exceed 5kg.

(9) Q: Under what circumstances do you need to equip a cord fixing bracket?

Fixtures provided or designed to use non-removable flexible cables or cords (power supply flexible cords or cords, interconnecting cables), and if they extend beyond the luminaire by more than 80mm, flexible cord fixing brackets are required.

(10) Q: How to complete the loop installation of lamps?

The loop installation of the lamp can only be done through the appliance coupler or terminal block.

Guangzhou Saida Testing Technology Co., Ltd. is a CNAS accredited laboratory. Lamps and LED drivers, rectifiers and other products are within the scope of our CNAS accreditation. If you have any related products and need to consult, please feel free to contact us:

Phone: 020-39211670 ext. 0

Fax: 020-39211640

E-mail: info@certitek.cn

Website: http://www.ctktest.com

Light-emitting diode lamps, also known as LED lamps, refer to appliances that can transmit, distribute, and change the light distribution of LED light sources, including all parts and components required to fix and protect the LED light source except the LED light source, and the connection to the power supply Necessary line accessories.

①Installation method; ②Type of light source; ③Protection class against electric shock; ④Protection class of enclosure; ⑤Mounting surface material and heat insulation material cover; ⑥Light control device; The above 6 points are the same and the structure is similar can be divided into the same unit.

Note: For certified products of LED lamps and LED control devices, for certified products with nominal power and measured power ≤ 25W and for certified products with nominal power or measured power> 25W, they cannot be in the same unit.

(2) Q: What are the requirements for parts used in products?

a) If the parts themselves are within the scope of CCC certification, they must have CCC certification.

Such as: power cord; AC electronic control device (driver) for LED module; electronic / inductive ballast for fluorescent lamp

b) If the component itself does not have CCC certification, try to choose a CQC certified component.

Such as: screw lamp holder; fluorescent lamp holder; terminal; flexible switch

c) Some optional parts can be added appropriately.

(3) Q: What are the forms of protection against electric shock?

Class Ⅰ-basic insulation, protective grounding;

Class Ⅱ-double insulation / reinforced insulation;

Class Ⅲ-Power supply voltage SELV Lamp working voltage SELV.

(4) Question: Which parts of Class Ⅰ lamps must be grounded?

There is only basic insulation between the live parts and can touch (when the installation is completed, when the light source or starter is replaced to open) or metal parts that are easily in contact with the support surface.

(5) Question: What positioning and protective measures should be taken for power terminals?

Insulation pads are generally placed under the terminal and fixed with double screws. The purpose is to prevent a strand of free conductor that may come out of the stranded conductor after wiring from contacting metal parts (for power conductors) or live parts (for grounding conductors) .

(6) Q: What are the restrictions on the use of self-tapping screws?

Unless there is a suitable locking device (such as a spring washer), self-tapping screws cannot be used to connect current-carrying parts; unless there are at least two at each connection, self-tapping screws cannot be used to provide ground continuity.

(7) Question: How to judge which parts of the glass or translucent cover need to be impact tested according to the requirements of fragile parts?

After the removal of these components, determine whether the IP protection level of the lamp is reduced, whether the protection against electric shock is still up to standard, and whether the protection against ultraviolet rays and light source sputtering hazards is still up to standard. If there is any negative judgment, it should be regarded as a fragile part and subjected to an impact test.

(8) Q: What are the mechanical performance requirements for live flexible cables used to hang lamps?

The flexible cable with a sufficiently large conductor cross-sectional area should be selected so that the stress of the conductor during suspension is not greater than 15N / mm2, and the weight of the weight suspended by the flexible cable cannot exceed 5kg.

(9) Q: Under what circumstances do you need to equip a cord fixing bracket?

Fixtures provided or designed to use non-removable flexible cables or cords (power supply flexible cords or cords, interconnecting cables), and if they extend beyond the luminaire by more than 80mm, flexible cord fixing brackets are required.

(10) Q: How to complete the loop installation of lamps?

The loop installation of the lamp can only be done through the appliance coupler or terminal block.

Guangzhou Saida Testing Technology Co., Ltd. is a CNAS accredited laboratory. Lamps and LED drivers, rectifiers and other products are within the scope of our CNAS accreditation. If you have any related products and need to consult, please feel free to contact us:

Phone: 020-39211670 ext. 0

Fax: 020-39211640

E-mail: info@certitek.cn

Website: http://www.ctktest.com

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn