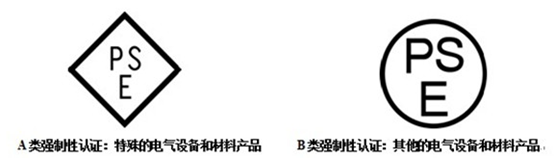

PSE certification is a mandatory safety certification in Japan, used to prove that motor and electronic products have passed safety standard tests under the Japanese Electrical and Material Safety Law (DENAN Law) or international IEC standards. According to Japan's DENTORL Law (Electrical Appliance and Material Control Law), 498 products entering the Japanese market must pass safety certification. Among them, 165 A-class products should obtain the diamond shaped PSE logo, and 333 B-class products should obtain the circular PSE logo.

Below, the editor will introduce the process and precautions for applying for PSE diamond certification for commonly used wire, cable, and plug products in our daily lives.

Common PVC and rubber wires for applying for Japanese PSE diamond mark certification:

1. Single core PVC insulated flexible wire: VSF, HVSF

2. Polyvinyl chloride insulated PVC sheathed oval wire: VCTFK, HVCTFK 3. Polyvinyl chloride insulated PVC sheathed round wire: VCTF, HVCTF4. Polyvinyl chloride insulated parallel flexible wire: VFF, HVFF 5. Natural rubber insulated natural rubber sheathed round wire CTF 6. Natural rubber insulated natural rubber sheathed oval wire CTFK 7. Natural rubber insulated chloroprene rubber sheathed round wire RNCTF8. Natural rubber insulated chloroprene rubber sheathed oval wire RNCTFK9. EP rubber insulated chloroprene rubber sheathed round wire PNCTF10. EP rubber insulated chloroprene rubber sheathed oval wire PNCTFK Common plug specifications for applying for Japanese PSE diamond mark certification: 1. Two plugs (7A 125V~), (12A 125V~), (15A) 125V~) 2. Triple plug (7A 125V~), (12A 125V~), (15A 125V~)

Application process for PSE of wire plug:

1. Submission of materials: Type Classification; Application for Conformity Assessment;

Understandings and Agreements;

Drawing; Power of Attorney; List of Inspection Facilities; Marking.2、 Confirm submission of materials and sample requirements

3. Delivery of materials and samples

4. Open case testing (usually lasting 4-5 weeks)

5. Factory review

6. PSE issues certificates

Main testing contents of the wire:

1. Electrical performance test;

2. Conductor resistance;

3. Structural inspection;

4. Structural dimension inspection;

5. Insulation thickness measurement;

6. Outer diameter measurement;

7. Tensile testing before aging;

8. Mechanical properties before insulation aging;

9. Printing scratch resistance;

10. Hot tensile test;

The main testing content of the plug is:

1. Structural inspection

2. Maintaining Strength

3. Temperature rise

4. Contact resistance

5. Insulation resistance

6. Dielectric withstand voltage

7. Heat resistance

8. Shell strength

9. Free fall

10. Logo

Essential equipment for factories:

Spark machine, aging chamber, vernier caliper, micrometer, dumbbell cutter, resistance bridge, voltage tester, insulation resistance tester, etc

Sample preparation precautions:

wire

1) Printing of wire samples: It is possible to simply print the wire specifications, such as VFF2x0.75 mm2

2) Insulation thickness: The average thickness should be above 90% of the standard value, and the thinnest point at any point should also be above 80% of the standard value. If the standard value of VFF insulation thickness is 0.8mm, the average thickness is above 0.72mm, and the thinnest point is above 0.64mm; The standard value of VCTF insulation thickness is 0.6mm, with an average thickness of 0.54mm or more and a thinnest point of 0.48mm or more. 3) Sheath protection: The average thickness should be above 90% of the standard value, and the thinnest point at any point should also be above 70% of the standard value. If the standard thickness of the VCTF sheath is 1.0mm, the average thickness is above 0.90mm, and the thinnest point is above 0.70mm, the plug 1) The printed content includes: rated current, rated voltage, plug model, manufacturer logo 2) The material between the two plug blades of the finished plug must pass the PTI 400V test, and attention should be paid to material selection.

Guangzhou Certitek Testing Technology Co., Ltd. (Certitek) was established in April 2006. It is a professional testing organization recognized by the China National Accreditation Service for Conformity Assessment (CNAS), with advanced national accredited laboratories and a professional team of engineers. The company specializes in testing and certification services for products such as wires, cables, plugs, and connectors. And on July 8, 2019, it reached a cooperation agreement with Japan Electric Cable Technology Center (JCT), a Japanese wire and cable testing and certification agency, becoming JCT's third overseas factory audit partner, which can provide efficient PSE certification and audit services for domestic Chinese enterprises.

It would be an honor for Saida to provide the necessary services for your company! Our company's contact information is as follows:

Guangzhou Saida Testing Technology Co., Ltd

Room 703, Tian'an Energy saving Technology Park Development Building, No. 555 Panyu Avenue North, Panyu District, Guangzhou City

Contact Person:

Ms. Chen Xi

Mobile phone: 13825088768

Email: service@certitek.cn

Ms. Jiang Chunyan

Mobile phone: 13760876900Email: sales1@certitek.cn

Ms. Chen Huomei

Mobile phone: 15975545208

Email: cs1@certitek.cn

Add.:Room703、705/7F, Development Building, Tian An Hi-Teck Ecological Park, No.555 North Road Panyu Avenue, Panyu District, Guangzhou City, 511400, China

Tel.:020-39211670 Fax:020-39211640 E-mail:info@certitek.cn